English Version

Beijing Key Laboratory of Multiphase Flow and Heat Transfer for Low Grade Energy Utilization

Beijing Key Laboratory of Multiphase Flow and Heat Transfer for Low Grade Energy Utilization

1. Research directions

The Beijing Key Laboratory of Multiphase Flow and Heat Transfer for Low Grade Energy Utilization was founded in 2011, April. Targeted for basic understanding and technology development for efficient utilization of low grade energy utilization, the laboratory has following research directions:

Multiscale heat transfer: Coupling effect of channel size and interfacial phenomena; micro/nano scale single-phase heat transfer; micro/nano scale phase change heat transfer; phase change heat transfer on uniform or heterogeneous wettability surface; multiscale heat transfer in macro-systems with surface modifications; micro/nano structure fabrication, characterization, modeling, measurement and applications; various heat pipe technologies.

Solar energy utilization: Large scale solar simulator design, fabrication and test; solar energy driven vapor generation; solar energy storage; solar energy receiver; solar energy utilization using nano-technologies; solar fuel.

Organic Rankine Cycle (ORC): Theory and application of low grade energy recovery; fluid selection for ORC system; thermodynamics; organic fluid heat transfer; ORC control and operation; integration strategy of ORC system; ORC system for flue gas energy extraction; ORC system for sea water desalination.

Supercritical CO2 power cycle: S-CO2 based advanced power cycle for coal fired power generation system; thermodynamics; S-CO2 flow and heat transfer; print circuit heat exchanger; system integration of S-CO2 power generation system; dynamics of S-CO2 power generation system; design and operation of S-CO2 boiler.

2. Faculties and staffs

The laboratory has eleven faculties and staffs, including three professors, four associate professors, two post-doctors, and two technicians. Faculties are active to perform academic exchangers. More than 30 students are in the laboratory to get master degree or Phd degree.

3. Major achievements and contributions:

3.1 Micro/nano flow and heat transfer

Three-atom-model: A three-atom-model was proposed to judge the type of boundary conditions (slip, non-slip and locking) at specific molecular (or atom) interactions between solid and liquid (see Li YX, et al., Nanoscale and Microscale Thermophysical Engineering 10 (2006): 109–141).

Absoluteness and relativity of boundary conditions: Slip lengths are found to be only dependent on interfacial parameter at solid-fluid interface. The boundary condition (slip, no-slip or locking) occurring in “microscale”, still exists in “macroscale”, which is called relativity of boundary condition. On the other hand, for any interfacial parameters at solid-fluid interface, the slip velocities approach zero when channel size is continuously increased, which is called absoluteness of boundary condition (see Xu JL and Li YX, Int J Heat and Mass Transfer 50 (2007) 2571–2581).

Switchable heat transfer in nanochannels: In nano-Janus system, by changing surface wettabilities of the two solid walls, driving forces, and wall temperatures, the fluid temperature gradient in channel height direction can be changed, and the heat flow sign can be switched between positive (heat transfer from hot wall to cold wall) and negative (heat transfer from cold wall to hot wall). The finding is useful for the development of temperature sensitive nano-devices (see Zhang LY, et al, Int J Heat Mass Transfer, 127 (2018) 761–771).

Microscale heat transfer enhancement using thermal boundary layer redeveloping concept: A new silicon microchannel heat sink composes of parallel longitudinal microchannels and several transverse microchannels to redevelop thermal boundary layer in each separated region, showing not only heat transfer enhancement, but also pressure drop reduction (Xu JL, et al., Int J Heat Mass Transfer 48 (2005) 1662–1674).

Corner nucleation, bubble explosion and three-region-heat-transfer: For boiling heat transfer in smooth silicon microchannels, bubbles prefer to nucleate in channel corners. Boiling flow behaves strong thermal non-equilibrium between vapor and liquid, inducing bubble explosion in ~ms timescale. Boiling number is identified as a key parameter to characterize the relative importance of wall interfacial effect relative to channel size effect. In terms of boiling number, heat transfer can be categorized as bubble nucleation dominant region, convective heat transfer dominant region, and mixed mechanism region (see Xu JL, et al., J. Micromech. Microeng. 15 (2005) 1344–1361).

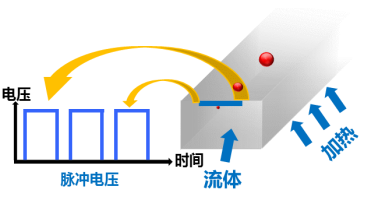

Seed bubble guided heat transfer in microchannels: For boiling in silicon microchannels, strong thermal non-equilibrium in microchannels delays the onset of bubble nucleation, causes flow instability and worsens heat transfer. Seed bubble guided heat transfer is proposed to overcome these challenges. Seed bubbles refer to micro/nano bubbles generated by pulse voltage signal at microchannel upstream. It is found that seed bubbles trigger boiling incipience at ultrasmall wall superheating such as <1K, completely suppress flow instability, and enhance heat transfer (see Xu JL, et al., Int J of Multiphase Flow 35 (2009) 773–790).

Dropwise condensation on superhydrophobic surface: A theoretical model is established. Nanostructure introduces both positive and negative contributions to condensation. The increased droplet population density and number of drop nucleation sites are positive contributions, while the decreased single drop heat transfer rate and additional nano-porous thermal resistance are negative contributions. Densely populated nano-pillars structure enhances heat transfer. Heterogeneous surface may keep long-term-operation without performance decay (see Xie J, et al., Adv. Mater. Interfaces 2017, 1700684; Xie J, et al., Int J Heat Mass Transfer, 127 (2018) 1170–1187).

3.2 Phase separation evaporator and condenser

Porous-wall-microchannels evaporator: Instead of solid walls without holes, porous walls introduce mass, momentum and energy exchange between neighboring channels. Bubble expansion in one channel depresses bubble in a neighboring channel, making the neighboring channel un-blocked. Such process is switched between different channels to cause high frequency “eye-blinking” interface oscillation. The wall temperature oscillation amplitude can be controlled within 0.1K (see Xu JL, et al., Int J of Heat and Mass Transfer 101 (2016) 341–353).

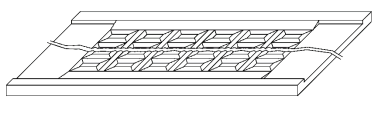

Microscale phase separation condenser: Microscale phase separation condenser was proposed. Lined pin fin arrays generate liquid passages and vapor passages alternatively in chip width direction. The decreased Gibbs free energy explains the phase separation mechanism. The decreased energy dissipation due to decreased interfacial area between the two phases accounts for pressure drop reduction. Heat transfer is improved by 74% compared with conventional microchannel condenser, while pressure drop is reduced (see Yu XJ, et al., Int J Heat Mass Transfer, 118 (2018) 439–454).

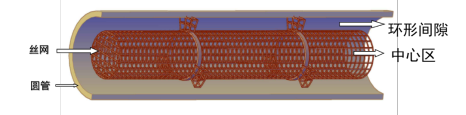

Large size phase separation condensers: Large size phase separation condenser is proposed. Mesh screen membrane is suspending in condenser tube, separating the tube cross section into an annular region and a core region. Due to the capillary forced induced phase separation, vapor flows in annular region to create wall attached thin liquid film to enhance heat transfer, while liquid flows in core region. A set of experiments, theoretical works and numerical simulations demonstrate the effectiveness. Commercial product is available and applications are expanded such as air-cooled condensers of coal fired power plant (see Chen HX, et al., Applied Energy, 2013, 112: 1283-1290; Xie J, et al., Energy 69 (2014) 787-800).

3.3 Heat pipes

Pulsating heat pipe: Pulsating heat pipe with smaller latent heat of evaporation behaves sine function oscillations for bubble displacements and velocities, with larger latent heat of evaporation display rectangular-shape bubble displacements and velocities (see Xu JL, et al., Int J Heat Mass Transfer, 48 (2005) 3338–3351).

Modulated porous wick evaporator for loop heat pipes: Conventional loop heat pipes use solid wall microchannels as the primary wick. We use the multiscale porous wick to replace microchannel structure. The loop heat pipe achieved an evaporator wall temperature of 63 oC at a heat load of 200W for anti-gravity operation, under which the heat flux attained 40 W/cm2, which is 1.7-6.7 times of those reported in references (see Xu JL, et al., Int J Heat and Mass Transfer 72 (2014) 163–176).

Switchable heat transfer mechanisms for heat pipe: By using super-hydrophilic evaporator and super-hydrophobic condenser, water populates in evaporator porous wick, and vapor covers condenser surface, yielding nucleation dominant heat transfer mechanism for both evaporator and condenser. This achieves increased heat transfer coefficients when heating load is raised (smart heat pipe, see Ji XB, et al., Nano Energy 38 (2017) 313–325).

3.4 Organic Rankine Cycles

Critical temperature criterion: By introducing non-temperature difference between heat carrier fluid and organic fluid, it is found that the fluid selection satisfies the critical temperature criterion: the thermal efficiency is higher if the fluid critical temperature approaches or is larger than the heat carrier fluid temperature entering the ORC system (see Xu JL and Yu C, Energy 74 (2014) 719-733).

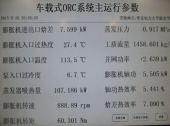

Non-equilibrium phenomenon in ORCs: The thermodynamics theory specifies saturation vapor at expander inlet and saturation liquid at pump inlet to reach maximum thermal efficiency. Our experiments show that a vapor superheating such as >10 K, and a liquid subcooling at pump inlet such as ~20 K, are needed to maximize the mechanical work, under which droplet impacting during expansion and bubble cavitation during pumping processes can be avoided. Thermal non-equilibrium is necessary in ORC system (see Yang YF, et al., Energy 90 (2015) 864-878).

3.5 Supercritical CO2 coal fired power plant:

Key issues for S-CO2 coal fired power plant: When supercritical CO2 Brayton cycle is used for coal fired power plant, the significantly increased flow rate causes extremely large boiler pressure drops. Our analysis shows that the recompression cycle incorporating reheating improves the efficiency, but boiler pressure drops deteriorate power plant performance. The partial flow strategy was proposed for the first time to yield boiler module design, and the boiler pressure drop is reduced according to the 1/8 principle. The work successfully solved the hydraulic issue (see Xu JL et al., Energy 157 (2018) 227-246).

Hybrid S-CO2 cycle for coal fired power plant: A single S-CO2 cycle is difficult to absorb flue gas heat in a wide range of 120–1500 °C. Novel methods are developed to cascade utilize flue gas heat, in which energies in high, moderate and low temperature levels are extracted by top cycle, bottom cycle or flue gas cooler (FGC), and air preheater, respectively. The separate-top-bottom-cycle (STB) is proposed, with six possible bottom cycles studied. The parameter coordination principle shares specific components for top and bottom cycles to form a connected cycle. The connected cycle has a power generation efficiency of 51.82% at main vapor parameters of 700 °C/35 MPa, significantly higher than available supercritical water-steam Rankine cycle power plant (see Sun EH, et al., Energy Conversion Management 172 (2018) 138-154).

Fundamental theory and modulation methods for multiscale phase interface

--Fundamental research of flow and heat transfer in micro/nanochannels

1. Background

Micro energy system refers to system in which the energy conversion and transport occur in a small volume to generate functions such as power supply. It has wide applications in electronics, aerospace and biology. Here, we focus on micro energy system with phase change as the key process. The coupling of interfacial effect at the wall surface and channel size effect is paid more attention. Major achievements are as follows:

2. Major achievement

2.1.Fundamental research of flow and heat transfer in nanochannels

A three-atom model and a new criterion number were proposed to identify the relationship between boundary condition and solid-liquid interfacial parameters.

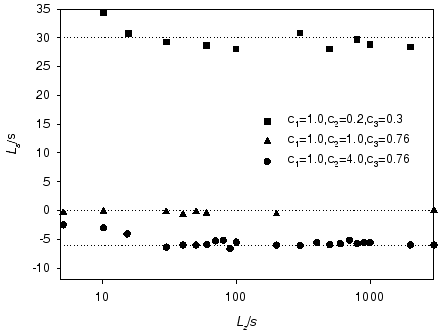

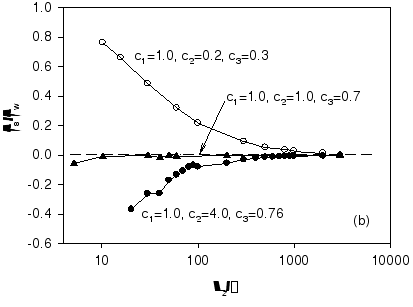

A hybrid atom-continuum model adjoining molecular dynamics and continuum mechanics is developed. The absoluteness and relativity of boundary conditions are found for the first time. The slip length is observed to be only dependent on interfacial parameters of solid/liquid atoms, not dependent on channel size (see Fig. 1a for absoluteness). Alternatively, slip velocity on solid wall is decreased to approach zero when channel sizes are continuously increased (see Fig.1b for relativity).

Fig. 1a Absoluteness principle of boundary condition

Fig. 1b Relativity principle of boundary condition

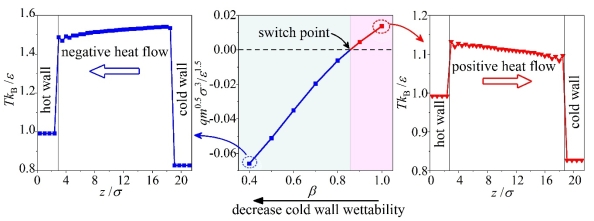

In nano-Janus system, by changing surface wettabilities of the two walls, driving force and wall temperatures, the heat flow sign in channel height direction can be switched between positive and negative (see Fig.2). The finding helps to develop novel nano-devices behaving temperature sensitive nature.

Fig. 2 Heat transfer is switched by varying wall wettabilities

2.2.Mechanisms and methods to enhance heat transfer in microchannels

The single-phase heat transfer in microchannels can be enhanced by using the thermal boundary layer re-developing concept (see Fig. 3).

Fig. 3 Thermal boundary layer redeveloping

The proposed microscale phase separation condenser not only enhances heat transfer, but also reduces pressure drop. Along axial flow direction, the vapor channel cross section is enlarged but the liquid channel cross section is decreased. The phase separation is performed with the lined pin fin array (see Fig.4).

Fig. 4 Conical phase separation condenser

Strong thermal non-equilibrium exists in silicon microchannels to delay the onset of bubble nucleation and induce the flow instability. Seed bubble guided heat transfer system uses seed bubbles in micro/nano size generated by pulse voltage signal at the microchannel upstream. Seed bubbles trigger the boiling incipience at ultra-small wall superheating such as <0.1 K, enhance heat transfer and eliminate the flow instability (see Fig.5).

Fig. 5a Generation and utilization of seed bubble

Fig. 5b Wall temperature decrease by seed bubble

2.3.Methods to indentify and eliminate flow instabilities in microchannel

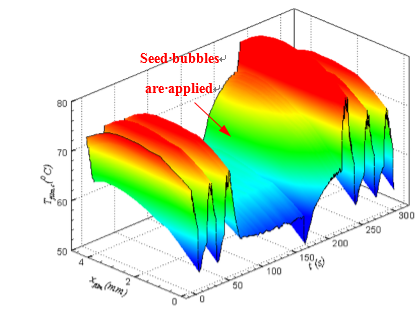

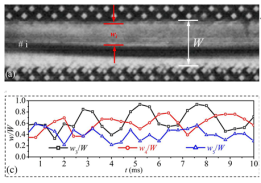

Wavelet decomposition method is employed to decouple boiling/evaporation oscillation signals over multi-time scales to identify different oscillation mechanisms (see Fig.6).

Gradient-porous-wall microchannels generate high frequency ‘‘eye-blinking” interface oscillation to eliminate the flow instability and achieve ultra-stable wall temperatures for boiling. (see Fig. 6a and 6b),

Fig. 6a Porous-wall microchannel Fig. 6b High frequency ‘‘eye-blinking”

3. Publications

[1] Xu JL, Li YX. Boundary conditions at the solid-liquid surface over the multiscale channel size from nanometer to micron. Int. J. Heat Mass Tran., 2007, 50: 2571-2581.

[2] Zhang LY, Xu JL, Chen QC, et al. Switchable heat transfer in nano Janus-interface-system. Int. J. Heat Mass Tran., 2018, 127: 761771.

[3] Xu JL, Gan YH, Zhang DC, et al. Microscale heat transfer enhancement using thermal boundary layer redeveloping concept. Int. J. Heat Mass Tran., 2005, 48: 1662-1674.

[4] Xu JL, Liu GH, Zhang W, et al. Seed bubbles stabilize flow and heat transfer in parallel microchannels. Int. J. Multiphas. Flow, 2009, 35: 773-790.

[5] Yu XJ, Xu JL, Yuan JD, et al. Microscale phase separation condensers with varied cross sections of each fluid phase: Heat transfer enhancement and pressure drop reduction. Int. J. Heat Mass Tran., 2018, 118: 439–454.

[6] Shen S, Xu JL, Zhou JJ, et al. Flow and heat transfer in microchannels with rough wall surface. Energ. Convers. Manage., 2006, 47: 1311-1325.

[7] Xu JL, Shen S, Gan YH, et al. Transient flow pattern based microscale boiling heat transfer mechanisms. J. Micromech. Microeng. 2005, 15: 1344-1361.

[8] Xu JL, Li YX, Wong TN. High speed flow visualization of a closed loop pulsating heat pipe. Int. J. Heat Mass Tran., 2005, 48: 3338-3351.

[9] Lyu Z, Xu JL, Yu XJ, et al. Wavelet decomposition method decoupled boiling/evaporation oscillation mechanisms over two to three timescales: A study for a microchannel with pin fin structure. Int. J. Multiphas. Flow, 2015, 72: 53–72.

[10] Xu JL, Yu XJ, Jin W. Porous-wall microchannels generate high frequency ‘‘eye-blinking” interface oscillation, yielding ultra-stable wall temperatures. Int. J. Heat Mass Tran., 2016, 101: 341–353

Fundamental theory and modulation methods for multiscale phase interface

-- Phase change heat transfer on micro/nanostructured surfaces

1. Background

Dropwise condensation on micro/nanostructured surface is a typical phase change heat transfer occurring in multi-time-length-scale. Superhydrophobic nanostructured surface promotes drop detachment which is beneficial to dropwise condensation. However, recent studies show that the nanostructured surface does not always enhance condensation heat transfer. The objective of this study is to (1) develop a criterion that governs the switch between droplet rolling, sliding and jumping; (2) At what condition does the superhydrophobic nanostructured surface enhance dropwise condensation? (3) How to design and fabricate robust condenser surface to resist nanostructure surface failure and keep better performance?

2. Major achievements

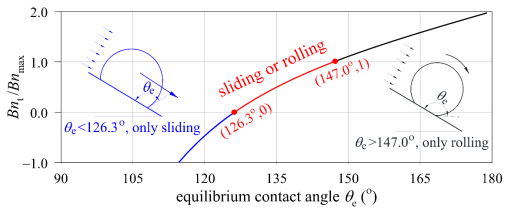

2.1.Drop detachment modes on inclined surface: wettability effect (see Fig. 1)

A mode selection criterion is developed for onset of sliding and rolling, which is only dependent on equilibrium contact angle e .

For 126.3<e<147.0, droplet rolls if Bn<Bnt and slides if Bn>Bnt, where Bnt is the transition Bond number.

For e<126.3, droplet only slides. For e>147.0, droplet only rolls.

147.0 is recommended as a new contact angle boundary between hydrophobicity and super-hydrophobicity.

Fig. 1 Mode selection criterion for sliding and rolling

2.2.Dropwise condensation on superhydrophobic nanograsses surface

Experiment (see Fig. 2)

Compared with smooth single-molecule-layer surface (SSML), fresh nanograsses surface (NGS) behaves smaller drop but has poorer heat transfer performance.

Collapse and breakage of nanograsses worsen heat transfer for long-term operation, and there is a decay limit of heat transfer coefficient after nanostructure failure.

Drop coalescence-induced-jumping dose not always occur. Instead, drop sliding or rolling causes nanostructure failure.

Mathematical model (see Fig. 2)

Three-drop detachment modes including jumping, sliding and rolling are included in the model. The predictions match experiment for both SSML and NGS.

Nanostructures have negative contributions to heat transfer, including reduced single drop heat transfer rate and additional nano-porous thermal resistance.

Enlarged nano-pillars spacing after nanostructure failure is the heat transfer deterioration mechanism. Heterogeneous surface with dense nano-pillars keeps sustainable and perfect performance.

Fig. 2 Experiment results and model analysis for condensation on nanograss surface (NGS)

2.3.Dropwise condensation on heterogeneous wettability surface

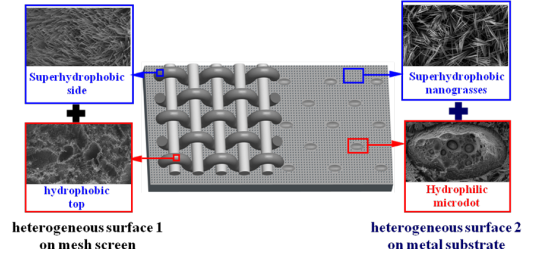

Fabrication of heterogeneous surface

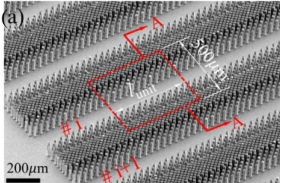

To achieve controllable condensation, novel method is proposed to fabricate two types of heterogeneous surface by coupling mesh screen and diffusion welding technique (see Fig. 3).

One is fabricated on mesh screen with hydrophobic micropits at weft wire top and superhydrophobic nanograsses elsewhere, utilizing heterogeneous corrosion under stress generated by diffusion welding.

The other is fabricated on copper substrate with arrayed hydrophilic microdots among superhydrophobic nanostructures, utilizing selective corrosion with the mask of mesh screen.

Fig. 3 Two novel heterogeneous surfaces

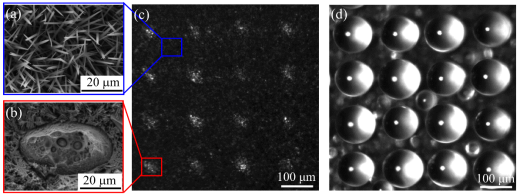

Condensation experiment on heterogeneous surface

Different from random distribution on nanostructure surface, condensate drops were limited on arrayed hydrophilic microdots of heterogeneous surfaces, yielding perfect droplet arrays (see Fig. 4).

The space between neighboring drops can be tuned in a reasonable range by mesh pore size, ensuring that drop coalescence-induced-jumping always occur.

The heterogeneous surface can be used as the next generation of functional surface to behave controllable dropwise condensation heat transfer and resist nanostructure failure for long-term operation.

Fig. 4 Structures and condensate droplet arrays on heterogeneous surface

3. Publications

[1] Xie J, Xu JL, Shang W, et al. Mode selection between sliding and rolling for droplet on inclined surface: Effect of surface wettability. Int. J. Heat Mass Tran., 2018, 122: 45–58.

[2] Xu JL, Xie J, He XT, et al. Water drop impacts on a single-layer of mesh screen membrane: Effect of water hammer pressure and advancing contact angles. Exp. Therm. Fluid Sci., 2017, 82: 83–93.

[3] Xu JL, Chen YY, Xie J. Non-dimensional numerical study of droplet impacting on heterogeneous hydrophilicity/hydrophobicity surface. Int. J. Heat Mass Tran., 2018, 116: 951–968.

[4] Xie J, Xu JL, Li X, et al. Dropwise condensation on superhydrophobic nanostructure surface, part I: long-term operation and nanostructure failure. Int. J. Heat Mass Tran., 2018, under review.

[5] Xie J, Xu JL, Shang W, et al. Dropwise condensation on superhydrophobic nanostructure surface, part II: Mathematical model. Int. J. Heat Mass Tran., 2018, 127: 1170–1187.

[6] Xie J, Xu JL, He XT, et al. Large scale generation of micro-droplet array by vapor condensation on mesh screen piece. Sci. Rep., 2017, 7: 39932.

[7] Xie J, Xu JL, Liu Q, et al. Coupling diffusion welding technique and mesh screen creates heterogeneous metal surface for droplets array. Adv. Mater. Interfaces, 2017, 4(23): 1700684.

[8] Cheng YP, Xu JL, Sui Y. Numerical investigation of coalescence-induced droplet jumping on superhydrophobic surfaces for efficient dropwise condensation heat transfer. Int. J. Heat Mass Tran., 2016, 95: 506–516.

Passive micro-nano structure cooler

--Technology and product

1. Plate heat pipe with expanded condenser and bionic capillary wicks

1.1 Basic principle:

Using extended condenser to increase condensation area by a set of channels prepared within fins.

Bionic capillary wicks were sintered on the inner evaporator surface. Integrated design of evaporator and condenser (heat sink) ensured tight contact between the heat pipe and the heat sink.

Many channels within fins coupled with wicks lead to a lots of miniature heat pipes operating simultaneously.

1.2 Technical index:

Increase the heat dissipation performance by 20% (Products for LED are shown in Fig. 1).

Reduce the center temperature by 20℃; decrease the weight of radiator by 50%.

Material cost can be saved by 50%. The detail comparisons with conventional LED radiator list as follows:

Test sample | Product size(mm×mm) | Product weight(kg) | Heating power(W) | Center temperature (oC) |

Identified sample | Ø170×200 | 1.3 | 100 | 57 |

Conventional sample | Ø310×250 | 3.3 | 100 | 81 |

Identified sample | Ø250×290 | 2.6 | 300 | 59 |

Conventional sample | Ø280×280 | 7.1 | 300 | 84 |

100W 100W 300W

Fig. 1 Radiator products for 100 and 300 W LED

1.3 Distinguish advantages:

Liquid supply towards the heating area is sufficient due to the extended condenser within solid fins, thus ultra-high heat flux can be sustained without reaching dry-out state at the heating area.

The fin pieces act not only as heat sinks but also condensers. The condensation heat transfer within solid fins ensures uniform temperature distribution along the fin height direction, increasing the fin efficiency.

It can be operated under the anti-gravity condition with compact volume and light weight. There is no contact thermal resistance between the evaporator chamber and the fin heat sink due to the integrated design.

1.4 Application fields

Heat dissipation of high heat-flux chips and their equipment in the fields of power electronics, aeronautics and astronautics, energy power, petrochemical and military, such as high-power lasers, lighting LED, control chips, fuel cells, new energy vehicles, laser, radar and large data computing centers, etc..

2. Loop heat pipe

2.1.Basic principle:

Three layers wicks were constructed within a loop heat pipe, the primary-layer wick is modulated porous wick instead of conventional microchannels in evaporator. The porous wick separates flow paths of vapor and liquid. Liquid is supplied within the porous stacks by the capillary force and evaporation happens at the solid-liquid-vapor interface. These structures simultaneously offer large valley size for vapor venting and small pore size for liquid suction.

The secondary monoporous wick and third wick layer not only function as the liquid supplier, but also function as the hydraulic and thermal barriers. The third wick layer had ultra-low thermal conductivity to greatly reduce the heat leakage from the evaporator to the compensation chamber.

2.2.Technical index (test product is shown in Fig. 2):

Evaporator temperature can be reduced to 20-50℃ of the conventional loop heat pipe, and the maximum heat flux can reach 40W/cm2.

The maximum anti-gravity height can reach 500 mm at the heating power of 300 W.

Fig. 2 Loop heat pipe

2.3 Distinguish advantages:

It can operate under the anti-gravity condition

Heat dissipation can be conducted at the high power and long transmission distance.

2.4 Application fields:

Heat dissipation of optoelectronic equipment in the fields of aeronautics and astronautics, energy power and military, etc.

3. Ultrathin heat pipe

3.1. Basic principle:

Bionic multiscale micro-nano structures were used as basic evaporator structure.

Super-hydrophilic evaporator and super-hydrophobic condenser are matched to modulate phase distribution.

Dominant heat transfer mechanisms of nucleation in evaporator and condenser have smart adaptive response of heat transfer coefficients with respect to heat fluxes.

3.2 Technical index (products are shown in Fig. 3):

Significantly lower heater temperatures by 30-40 oC (~100W/cm2).

Evaporation heat transfer coefficient can be increased by 2.4 times.

Condensation heat transfer coefficient can be increased by 4 times.

3.3 Distinguish advantages:

Small volume and light weight.

Greatly improve the stability, reliability and service life of the equipments.

3.4 Application fields:

Heat dissipation of compact electronic equipments, such as notebook computer, microprocessor and so on.

Fig. 3 Ultrathin heat pipe (the thickness can be less than 1.3 mm)

4. Inventions and awards

We have mastered a series of key technologies, and have won 8 invention patents and technology awards for many times (see Fig. 4).

Fig. 4 Innovation award and excellent innovative product certificate

5. Publications

[1] Xianbing Ji, Jinliang Xu, Hongchuan Li. Switchable heat transfer mechanisms of nucleation and convection by wettability match of evaporator and condenser for heat pipes. Nano-structured surface effect. Nano Energy, 2017, 38: 313-325.

[2] Jinliang Xu, Xianbing Ji, Wolong Yang, Ziwei Zhao. Modulated porous wick evaporator for loop heat pipes: Experiment. International Journal of Heat and Mass Transfer. 2014, 72: 163-176.

[3] Xianbing Ji, Jinliang Xu, Aime Marthial Abanda, Qiang Xue. A vapor chamber using extended condenser concept for ultra-high heat flux and large heater area. International Journal of Heat and Mass Transfer. 2012, 55: 4908-4913.

[4] Xianbing Ji, Hongchuan Li, Jinliang Xu, Yanping Huang. Integrated flat heat pipe with a porous network wick for high-heat-flux electronic devices. Experimental Thermal and Fluid Science, 2017, 85: 119-131.

6. Cooperation ways:

Patent transfer, secondary development, industrialization and industrial demonstration.

Organic Rankine Cycle Power Generation System

1. Introduction

Organic Rankine Cycle (ORC) is a key technology to convert low grade energy such as flue gas energy and renewable energy such as solar energy into mechanical power. We focused on the coupling mechanism between heat carrier fluid and organic fluid, organic fluid selection, organic fluid condenser, and prototype of ORC system development. Major achievements are as follows:

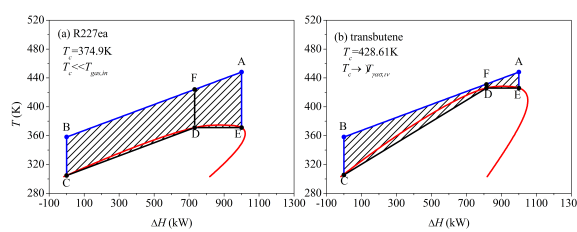

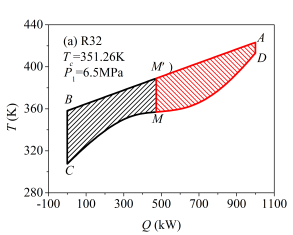

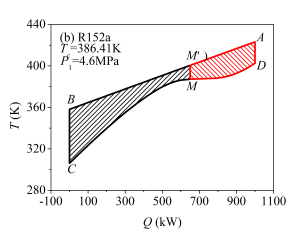

2. Organic fluid selection criterion

The selection of working fluids for ORC is scattered in the literature, and there is no general guideline for fluid selection. In this project, the non-dimensional temperature difference is proposed to characterize how better the heat source fluid matches the ORC system. In terms of this, it is found that the thermal efficiency reaches maximum or is better when the critical temperature of a fluid approaches or is larger than the heat source temperature. The critical temperature is a unique criterion for fluid selection, providing a general guideline for ORC fluid section. This conclusion is correct for sub-critical ORC and super-critical ORC (see Figs.1-2).

Fig.1 Decreased integration temperature difference by raising critical temperatures of organic fluid(subcritical ORC)

Fig.2 Decreased integrated temperature difference by raising critical temperature of organic fluid(supercritical ORC)

3. The phase separation condenser

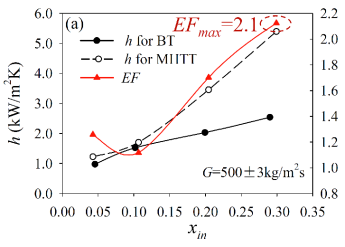

The phase separation condenser is proposed and developed in our laboratory. The condensation heat transfer coefficient can be two times of that for bare tube. The ORC system performance is improved when the phase separation condenser is integrated with the ORC system(see Figs.3-4).

Fig.3 The principle for phase separation condenser (US patent US 2014/0138861)

Fig.4 The enhanced condensation heat transfer with maximum enhancement factor of 2.1

4. ORC prototype demonstration and application

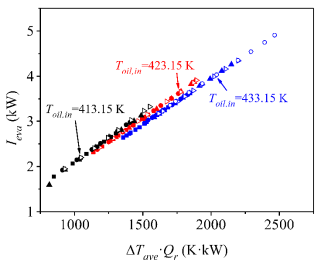

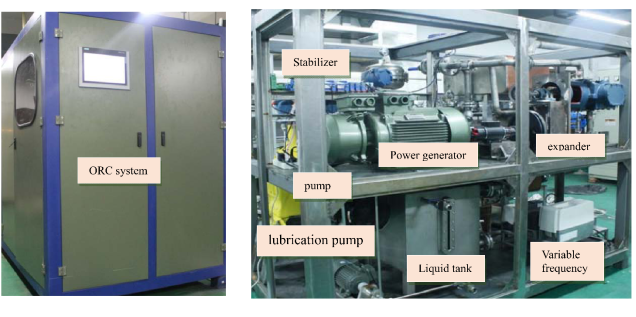

The whole ORC system was demonstrated including fluid selection criterion, phase separation condenser, non-equilibrium criterion to avoid vapor cavitation and control system. At the heat source temperature of ~100oC, the net thermal efficiency can reach 6.35%, which is the highest by comparing with the existing literature. Experiments show that the system can self-adapt the variations of heat source parameters such as heat carrier fluid inlet and outlet temperatures and flow rate, and cooling source parameters. The system can operate in off-grid mode, but the generated electricity can also be transmitted to power grid(see Figs.5-7).

Fig.5 The experiment verified relationship between integration temperature difference and exergy destruction in heat exchanger

Fig.6 The ORC system developed in our laboratory

| ||

|

|

|

Fig.7 The ORC system focusing on expander, power generator and control system

5. Publications:

[1] Chen QC, Xu JL, Chen HX, A new design method for Organic Rankine Cycles with constraint of inlet and outlet heat carrier fluid temperatures coupling with the heat source, Applied Energy, 2012, 98: 562-573.

[2] Xu JL, Liu C. Effect of the critical temperature of organic fluids on supercritical pressure Organic Rankine Cycles. Energy, 2013, 63): 109-122.

[3] Chen HX, Xu JL, Li ZJ, Xing F, Xie J. Stratified two-phase flow pattern modulation in a horizontal tube by the mesh pore cylinder surface. Applied Energy, 2013, 112: 1283-1290.

[4] Chen QC, Xu JL, Sun DL, Cao Z, Xie J, Xing F. Numerical simulation of the modulated flow pattern for vertical upflows by the phase separation concept. International Journal of Multiphase Flow, 2013, 56: 105-118.

[5] Xie J, Xu JL, Xing F, Wang ZX, Liu H. The phase separation concept condensation heat transfer in horizontal tubes for low-grade energy utilization. Energy, 2014, 69: 787-800.

[6] Miao Z, Yang XF, Xu JL, Zou JH, Development and dynamic characteristics of an Organic Rankine Cycle, Engineering Thermophysics, 2014, 59(33):4367-4378.

[7] Miao Z, Xu JL, Yang XF, Operation and performance of a low temperature organic Rankine cycle, Applied Thermal Engineering, 2015, 75:1065-1075.

[8] Wang HR, Xu JL, Yang XF, Miao Z, Yu C, Organic Rankine cycle saves energy and reduces gas emissions for cement production, Energy, 2015, 86:59-73.

[9] Yang XF, Xu JL, Miao Z, Zou JH, Yu C, Operation of an organic Rankine cycle dependent on pumping flow rates and expander torques, Energy, 2015, 90:864-878.

[10] Yu C, Xu JL, Sun YS, Transcritical pressure Organic Rankine Cycle (ORC) analysis based on the integrated-average temperature difference in evaporators, Applied Thermal Engineering, 2015, 88:2-13.

[11] Yang XF, Xu JL, Miao Z, Zou JH, F Qi FL. The definition of non-dimensional integration temperature difference and its effect on organic Rankine cycle, Applied Energy, 2016, 167:17-33

[12] Miao Z, Xu JL, Zhang K, Experimental and modeling investigation of an organic Rankine cycle system based on the scroll expander, Energy, 2017,134:35-49.

[13] Cao S, Xu JL, Li YZ, Yan YY. Condensation heat transfer of R245fa in a shell-tube heat exchanger at slightly inclined angles, International Journal of Thermal Sciences, 2017, 115:197-209.

[14] Cao S, Ji XB, Xu JL, R245fa condensation heat transfer in a phase separation condenser, Experimental Thermal and Fluid Science, 2018, 98:346-361.

[15] Miao Z, Yang XF, Xu JL, Zou JH. Development and dynamic characteristics of an organic Rankine cycle. Chin Sci Bull, 2014, 59(33):4367-4378.

Solar energy conversion and utilization at medium-high temperature

Background: Energy is a base resource for sustainable development of human society. Among various energy resources, solar energy attracts special attention since it is an abundant and inexhaustible energy source. Efficient strategies for solar energy conversion include photovoltaic, solar thermal conversion and artificial photosynthesis. The photoelectric conversion converts solar energy into electricity by the photovoltaic effect. While the production of solar panel requires large amount of energy with high cost that induces serious pollution to the environment. Alternatively, radiant energy can be transformed into thermal energy by the photothermal effect of materials. This strategy has gained most interest due to its extremely high efficiency. Artificial photosynthesis is a photochemical process that replicates the natural photosynthesis, a process that converts sunlight, water and carbon dioxide into hydrocarbons. In this background, we propose optofluidic concept for the study of solar thermal and/or chemical conversion with focus on multi-phase flow opportunities in sunlight-based steam or fuel production processes. The research offer new insights into the related physical processes, and could stand for a basis to design novel systems for engineering application.

Research field:Photothermal physics, Solar evaporation, Plasmonic self-assembly, Wastewater sterilization and seawater desalination, Water splitting coupling CO2 reduction, etc.

Research progress:

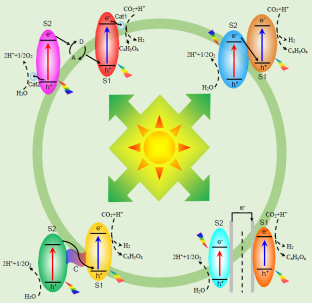

1. Z-scheme:The possibilities of applying two-photon concept to the field of solar fuels are highlighted. A wide range of strategies including the indirect combination of two semiconductors by a redox couple, direct coupling of two semiconductors, multicomponent structures with a conductive mediator, related photoelectrodes, as well as two-photon cells are discussed for light energy harvesting and charge transport. This gives a new perspective on artificial photosynthesis, outlining an encouraging roadmap towards solar fuels.

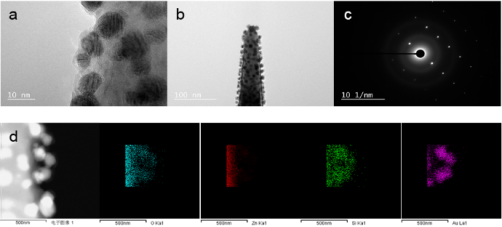

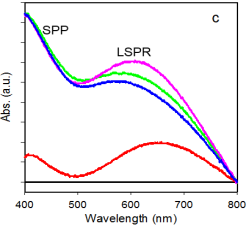

2. Light-harvesting antenna: The ordered nanotube arrays were prepared and their wettability was studied. The nanotube film has a strong hydrophilic property. The hydrophilicity was further improved after annealing. The hydrophilicity was enhanced with the increase of the diameter of nanotube and the excessive oxidation on surface. Moreover, plasmonic gold nanoparticles and dielectric silicon oxide are sequentially deposited on the surface of ZnO nanorods to tune their photoelectric performance. The results show that the optical design of plasmonic coupling with dielectric spacer dramatically leads to an outstanding photocurrent enhancement, which is ~ 4-28 times higher than that of the other counterparts.

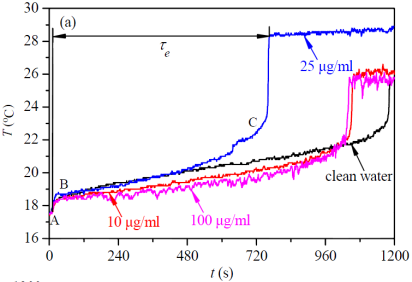

3. Solar evaporation and artificial leaf:Solar water evaporation are explored through a hanging droplet containing plasmonic nanoparticles. These nanoparticles induce multiple scattering events, increasing photon absorption and concentrating the light within the mesoscale domain, leading to an intense collective heating that trigger the evaporation. The droplets with different initial-particle-concentrations lead to evaporation at various rates and an optimal initial-particle-concentration can be expected. In addition, we propose the concepts of micro/nano materials and optofluidic systems for solar energy harvesting and CO2 utilization. The research consists of solar chemistry research of porous composite catalysts as well as innovation of microfluidic techniques in the field of photochemistry. Micro-fluid networks are introduced to modulate two-phase flow patterns over the catalyst surface to improve the performance of artificial photosynthesis.

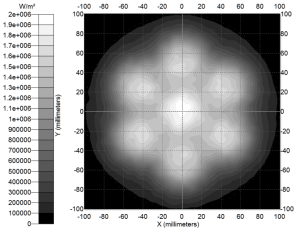

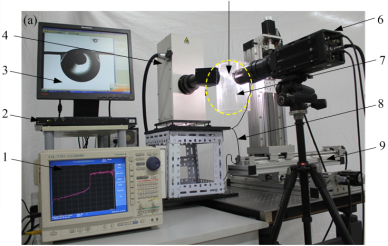

4. High-flux solar simulator:The simulator consists of an optical system, a power source, an air cooling system, a control system, and a calibration system. Seven xenon short-arc lamps are employed with each consuming 10 kW. The seven lamps have a common focal plane that can be tuned in the range of 60-120 mm with the lamp module traveling the distance in a range of 0-300 mm. The irradiant flux distribution can be tailored by varying the power capacities and/or moving the focal plane locations. The peak flux and temperature exceed 4 MW/m2 and 2300 K, respectively, for the full power capacity.

|

|

5. Publications:

[1] Liu GH, Cao H, Xu JL. Solar evaporation of a hanging plasmonic droplet, Solar Energy, 170 (2018) 184-191.

[2] Liu GH, Xu JL, Wang KY. Solar water evaporation by black photothermal sheets, Nano energy, 41(2017)269-284.

[3] Liu GH, Du K, Xu JL, et al. Henrik Jakobsen. Plasmon-dominated photoelectrodes for solar water splitting. Journal of Materials Chemistry A, 5(2017)4233-4253.

[4] Liu GH, Du K, Haussener S, et al. Charge transport in two-photon semiconducting structures for solar fuels. ChemSusChem, 9(2016)2878-2904.